Some electronic devices need to operate in harsh conditions, which, apart from extreme temperatures, include exposure to vibrations, moisture, and radiation. A particular subset of these devices and electronic components is designed to operate when exposed to ionizing radiation. This includes primarily equipment used for monitoring nuclear installations, scientific and medical equipment utilizing heavy ions for treatment, and devices operating in space.

A rapidly growing segment of the Cube Satellite market involves using commercial off-the-shelf (COTS) components for spacefaring missions. Originally designed for less demanding applications, these solutions usually don’t come with dedicated ICs that can withstand the harsh conditions in space. One option, already successfully being employed, is to shield sensitive components against radiation, which requires extensive testing and validation.

Memory chips are especially susceptible to radiation, and thus require special attention and thorough testing to ensure they can operate effectively, even in extreme environments. Antmicro has developed a flexible memory testing framework that provides a series of FPGA-driven memory testers originally developed to facilitate research and testing against Rowhammer attacks, and allows initializing different types of DRAM memories to perform low-level read/write operations. Since all the hardware, software and RTL components of the DRAM testing suite have been open sourced, they can be easily adjusted for particular experimentation scenarios, e.g. inspecting memory vulnerabilities to radiation.

In this article we will describe how we use our DRAM testing framework to test different types of memories against radiation, and show how this approach can be extended to other types of components and testing scenarios.

Radiation effect on DRAM memories

The two main types of radiation relevant for DRAM memories operating in space are electromagnetic and particle radiation, including alpha, beta, and proton radiation. Alpha radiation (Helium ions) is extremely ionizing and tears down electrons from the particles it hits. The heavy ions made of atoms and particles heavier than Helium, e.g. Xenon, Krypton, or Argon, are electrically charged and get accelerated when hit by alpha rays. This causes them to subsequently impact electronic components, which may lead to circuit malfunction, switching bits stored in memories, affecting the CPU state machine execution, etc. On the other hand, ground-based data centers that store sensitive data can eventually be exposed to residues of Coronal Mass Ejections (CME) from the Sun, which may lead to data corruption.

While dedicated space-grade equipment offers high reliability and radiation tolerance by design, commercial components often provide better performance and more flexibility. Recently, utilizing commercial components, such as 10GbE equipment, has become more widespread in the space industry. In particular, LPDDR5 memories that are widely used with modern SoCs, including the NVIDIA Jetson Orin and Jetson Thor series of SoMs that Antmicro often works with, are a popular choice for processing platforms. LPDDR5 offers high memory transfer speeds with huge bit density, however, this type of memory operates at a very low VDDQ IO voltage standard (0.5V or 0.9V), which makes it extremely susceptible to ionizing radiation. When hit with heavy ions, a DRAM cell can trigger a so-called single-event upset. This may lead to bit flips that actually change the memory content, either temporarily or permanently.

In order to use LPDDR5 memories in radiation-hardened scenarios, it is crucial to first verify and assess the memory’s vulnerability to such radiation, then shield it, and then repeat the validation to assess the overall radiation durability. The energy and type of particles used for radiation immunity testing in most cases needs to be adjusted to the specific IC package and silicon-mounting technology to ensure that the energy discharge will happen inside the silicon die under test.

Using Antmicro’s FPGA-driven DRAM experimentation framework for radiation testing

A few years back, in collaboration with Google, Antmicro developed a modular, fully configurable research and experimentation framework targeting various types of DRAM memories, including (LP)DDR4 and (LP)DDR5. Originally developed to research the Rowhammer vulnerability, it has since been extended to other use cases involving new types of attacks, but also different experimentation scenarios. More details about the framework can be found on the Google Security Blog in a recent article titled Supporting Rowhammer research to protect the DRAM ecosystem.

Antmicro’s open source DRAM testing suite has already been used in several scientific experiments aimed at memory characterization and benchmarking in severe conditions (including high temperatures), conducted by research institutes such as ETH Zurich. Since the FPGA design allows us to initialize the memory and fill it with some known bit pattern, it is possible to expose it to radiation and outline the conditions at which the memory content will be corrupted. This FPGA-driven flow provides full control over the process.

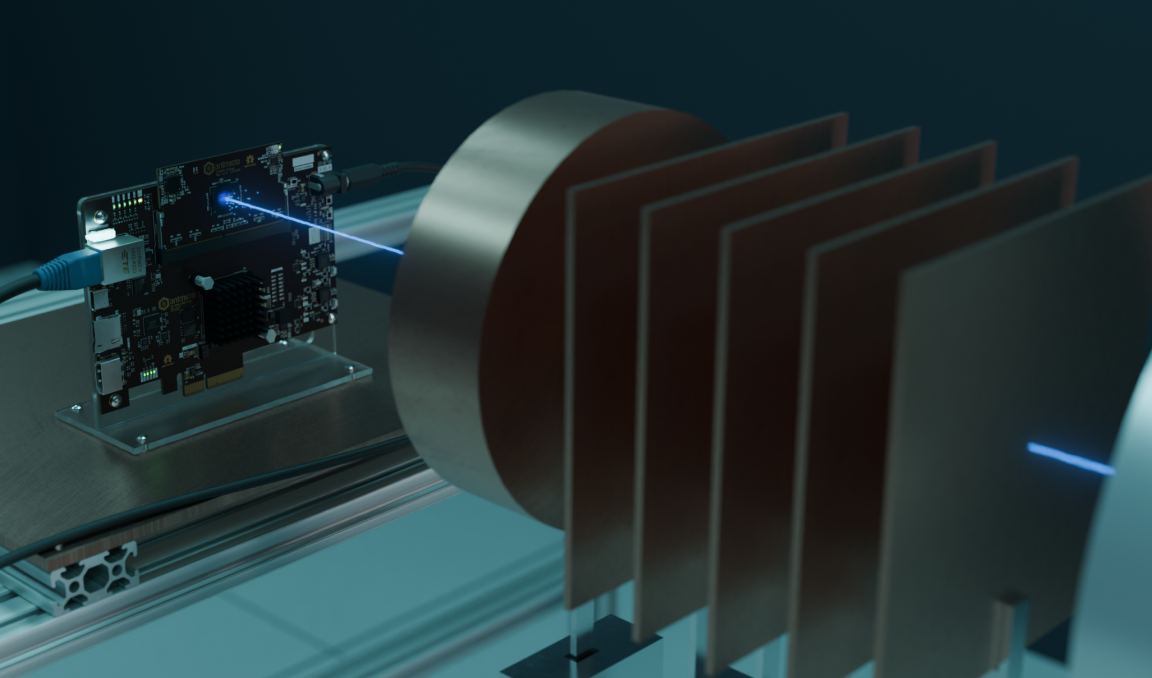

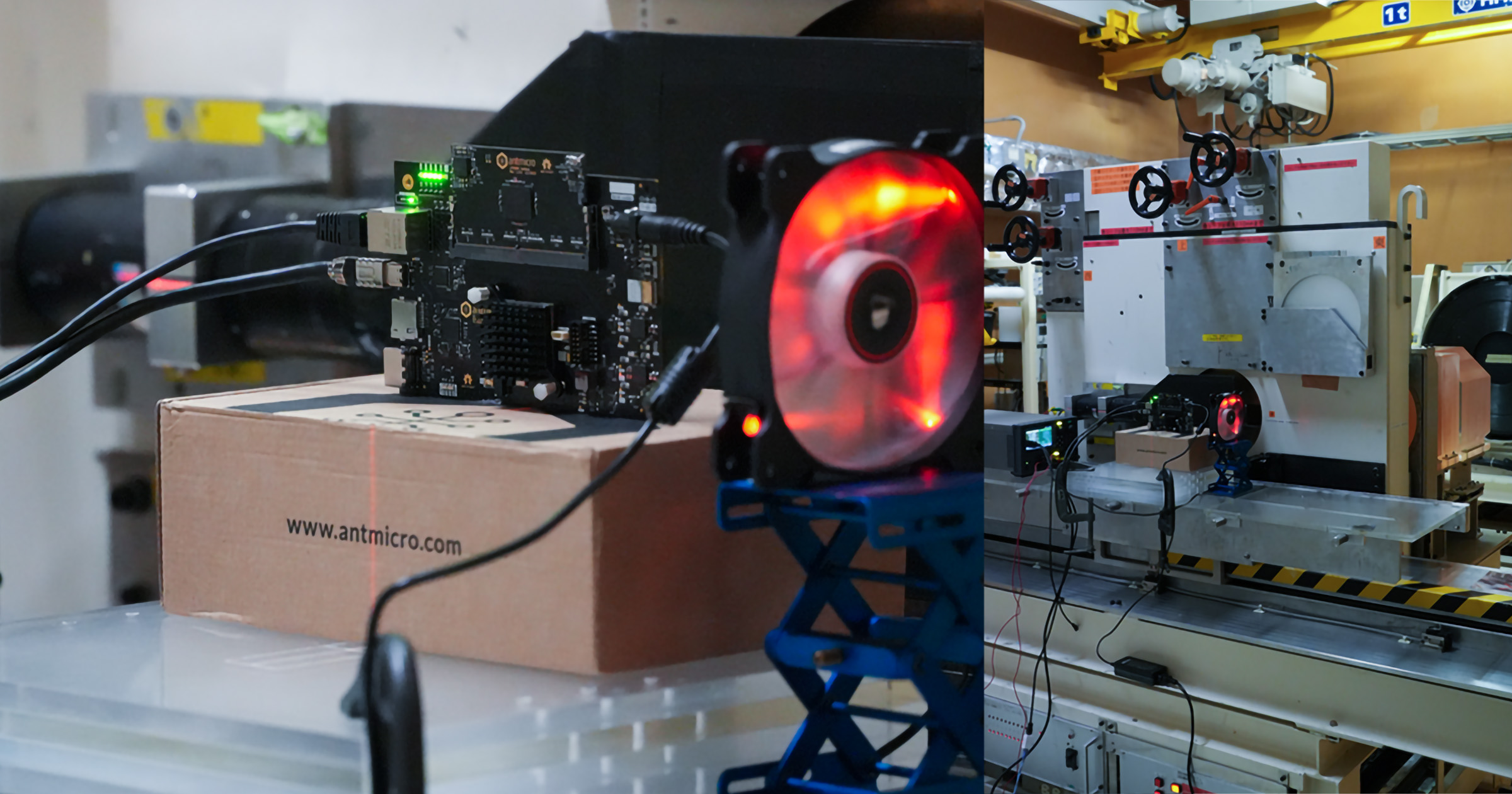

One of the hardware platform supported by the memory testing framework is the SO-DIMM DDR5 Tester that can work with regular off-the-shelf SO-DIMM DDR5 memories, but also with single-chip LPDDR5 memories, using a dedicated LPDDR5 Testbed. The hardware setup is complemented by the custom software and RTL design which allow performing LPDDR5 memory initialization and executing low-level read/write/refresh commands. Together, they provide a perfect experimental setup for inspecting the behavior of particular LPDDR5 chips when exposed to an ionizing beam.

Antmicro’s SO-DIMM DDR5 Tester was used in radiation tests conducted at the Heavy Ion Medical Accelerator in Chiba, Japan, along with custom space-grade equipment we developed for our customer.

Open source-driven radiation testing with Antmicro

Antmicro can help you customize the memory tester design for your use case and coordinate the radiation testing process. We can expose the specific IC (FPGA, SoC, MCU, RAM, DC/DC) that needs to be tested on dedicated PCBs that are tailored to the beam aperture, and implement an FPGA-driven control system to control the IC under test. We can also prepare software (BSPs, RTL designs) that will validate the data transfers and verify data coherence in the ICs exposed to radiation. The entire testing process can be orchestrated with unit tests, hardware-in-the-loop setups, and Protoplaster as our unified testing framework.

To learn more about Antmicro’s engineering services, or discuss how we can help you develop a custom testing platform, make sure to reach out to us at contact@antmicro.com.